Rotor Die Casting Machine Manufacturers 15 Seconds/Piece Wholesale - WEDE

Product details of the rotor die casting machine manufacturers

Product Specification

Cycle Time: 15 Seconds/Piece

Origin: Huzhou, China

Transport Package: Ply-Wooden Case

Product Introduction

The raw materials of WEDE rotor die casting machine manufacturers is procured from reliable vendors across the world. The products are internationally certified and have a longer service life than other products. For Ningbo Hi-Tech WEDE Motor Machines Co.,Ltd. it is very important to set up the quality system.

Efficient Precision Die Casting

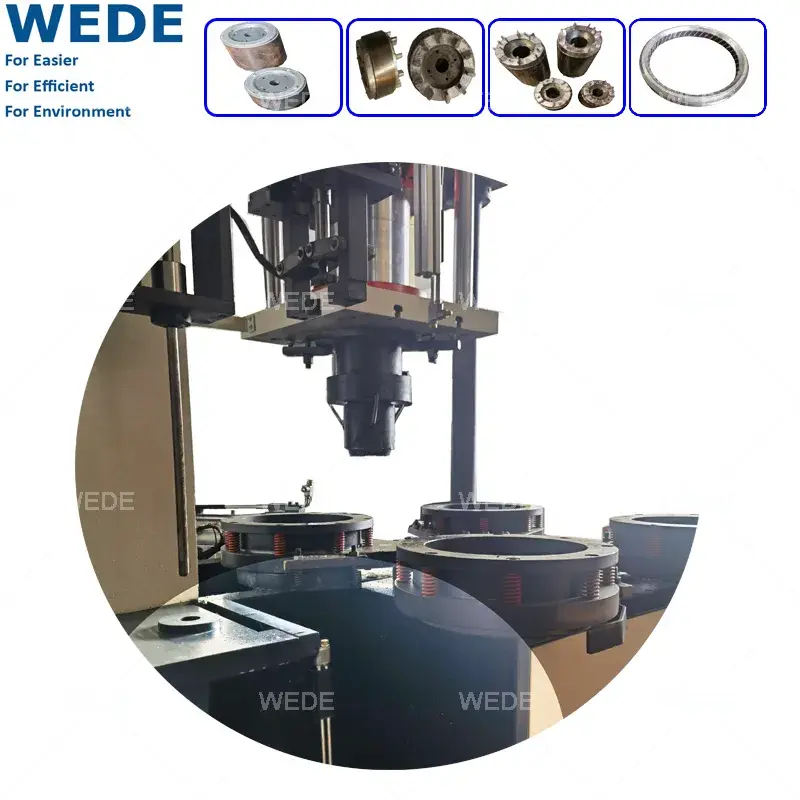

High precision vertical pressure casting machine specifically designed for rotor casting, equipped with servo system for superior performance and energy efficiency. This aluminum rotor injection machine offers semi-auto capabilities, including casting, divider, lubrication, and unloading, making production processes seamless and efficient. Choose this advanced machine for fully automated operation and exceptional quality output in rotor die casting.

Product Display

Efficient, precise, versatile, durable

Precision Casting Machine: Vertical Power and Precision

The Vertical Pressure Casting Machine for Rotor is equipped with a servo system and main driven by big power, providing high precision die casting capabilities. With 4 rotary stations running, this Rotor Casting Machine offers fast and efficient production, while also featuring auto-loading, auto-unloading, and environment protective shield options. The aluminum rotor injection machine can be selected to equip with aluminum filling robot, auto dummy shaft draw back device, and aluminum remnants return conveyor, making it a versatile solution for fully auto running rotor die casting operations.

Material Introduction

The vertical pressure casting machine for rotors is constructed with a sturdy frame and beam made of welded steel, ensuring durability and stability. Equipped with a servo system, the machine offers high precision operation, driven by powerful motors and precise indexing for increased efficiency and accuracy. With capabilities for semi-automatic operation and various optional features like loading robots and protective shields, this rotor casting machine is versatile and efficient for producing aluminum rotors.

FAQ

Company Feature

• WEDE Motor Machines's location has traffic convenience with multiple traffic lines joining up. This contributes to the transportation and ensures the timely supply of products.

• Under the constant market development and product innovation, our company has gradually established a market strategy. In this way, we focus on the sales of key products and the expansion of the domestic market, and then realize the product layout in the national region.

• WEDE Motor Machines's researchers, technicians, and quality inspectors are the powerful guarantee for continuous development.

For bulk purchase of the products, please contact us.

Add:

Office: Hi-tech District Ningbo China

Office: FengHua Ningbo China

Factory: Suzhou, China

Factory: Taizhou, China