Die Casting Machine for Sale Aluminum Casting Wholesale - WEDE

Product details of the die casting machine for sale

Product Specification

Stations No.: 4

HS Code: 8454309000

Processing Part: Aluminum Casting

Cycle Time: 15 Seconds/Piece

Production Capacity: 60PCS/Year

Product Description

With the help of experienced craftsman, WEDE die casting machine for sale is produced following the highest production standards. Reliable quality and outstanding durability are the competitive advantages of the product. die casting machine for sale plays an important role for the development of WEDE.

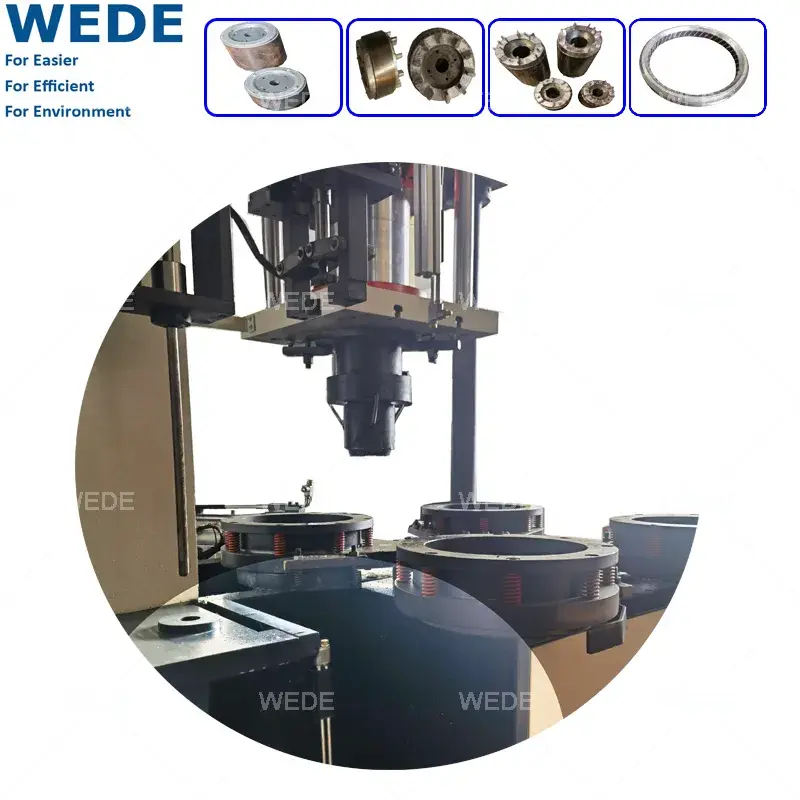

Efficient Precision Die Casting

High precision vertical pressure casting machine specifically designed for rotor casting, equipped with servo system for superior performance and energy efficiency. This aluminum rotor injection machine offers semi-auto capabilities, including casting, divider, lubrication, and unloading, making production processes seamless and efficient. Choose this advanced machine for fully automated operation and exceptional quality output in rotor die casting.

Product Display

Efficient, precise, versatile, durable

Precision Casting Machine: Vertical Power and Precision

The Vertical Pressure Casting Machine for Rotor is equipped with a servo system and main driven by big power, providing high precision die casting capabilities. With 4 rotary stations running, this Rotor Casting Machine offers fast and efficient production, while also featuring auto-loading, auto-unloading, and environment protective shield options. The aluminum rotor injection machine can be selected to equip with aluminum filling robot, auto dummy shaft draw back device, and aluminum remnants return conveyor, making it a versatile solution for fully auto running rotor die casting operations.

Material Introduction

The vertical pressure casting machine for rotors is constructed with a sturdy frame and beam made of welded steel, ensuring durability and stability. Equipped with a servo system, the machine offers high precision operation, driven by powerful motors and precise indexing for increased efficiency and accuracy. With capabilities for semi-automatic operation and various optional features like loading robots and protective shields, this rotor casting machine is versatile and efficient for producing aluminum rotors.

FAQ

Company Feature

• Since it was founded in our company has been experiencing continuous struggle and challenge for years. We have accumulated a lot of experience and abundant economic strength. It can promote the multiplication of our benefits.

• WEDE Motor Machines's sales network is spread all over the world.

• WEDE Motor Machines provides comprehensive and professional services in accordance with the actual needs of customers.

We can provide you with high-quality products and look forward to your cooperation with us.

Add:

Office: Hi-tech District Ningbo China

Office: FengHua Ningbo China

Factory: Suzhou, China

Factory: Taizhou, China