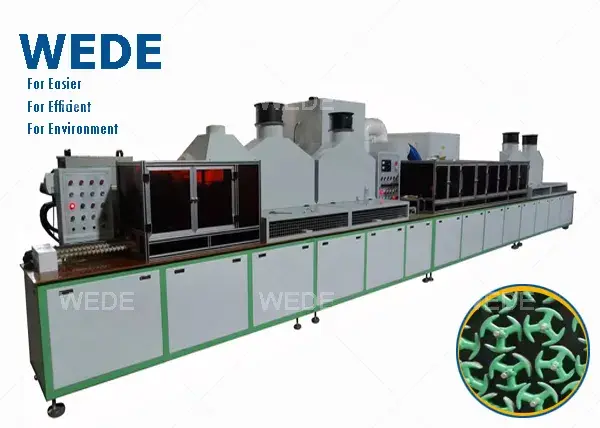

Powder Coating Plant Tailor Design Refer to Coating Parts Size by WEDE

Efficient, Precise, Durable, Versatile

Experience the efficiency and automation of our PLC Control Epoxy Powder Coating Machine for Rotor, perfect for mass production with high-quality results. This powder coating equipment offers a wide application range and features fully automatic working cycles, making it an essential tool for automotive and industrial motor applications. Elevate your production process with our reliable and customizable powder coating machine.

Product Display

Efficient, Versatile, Precise, Durable

Efficient, Precise, Automated Rotor Coating

The PLC Control Epoxy Powder Coating Machine for Rotor offers wide application and high quality powder process, suitable for mass production with a powder recycling function. It provides a fully automatic working cycle, high efficiency, automation, and productivity, as well as the option for customization. This powder coating equipment is ideal for use in automotive and industrial motor applications, offering a curing method through a high-frequency process and adjustable coating thickness for optimal results.

Material Introduction

The PLC Control Epoxy Powder Coating Machine for Rotor is constructed using high-quality materials to ensure durability and efficiency in the powder coating process. The machine is equipped with a pre-heating zone, cooling zone, resin coating zone, and curing zone for optimal performance. With wide application in automotive and industrial motor industries, this powder coating equipment offers high efficiency, automation, and productivity, making it an essential component for mass production processes.

FAQ

Company Advantages

· The design of WEDE powder coating plant can be customized to meet various target markets.

· We have a professional lab to ensure high quality for this product.

· Ningbo Hi-Tech WEDE Motor Machines Co.,Ltd. emphasize quality oversight of qualification activities in manufacturing area.

Company Features

· Ningbo Hi-Tech WEDE Motor Machines Co.,Ltd. is an internationally active manufacturer of powder coating plant with headquarters in China. We have many years of experience in this industry.

· Ningbo Hi-Tech WEDE Motor Machines Co.,Ltd. has advanced technology and sophisticated equipment.

· We have been working for the last several years in catering to the niche market. We have a very distinguished clientele and we are constantly striving to make them the best in the world. Get info!

Application of the Product

powder coating plant of WEDE Motor Machines can be widely used in various fields.

WEDE Motor Machines is rich in industrial experience and is sensitive about customers' needs. We can provide comprehensive and one-stop solutions based on customers' actual situations.

Add:

Office: Hi-tech District Ningbo China

Office: FengHua Ningbo China

Factory: Suzhou, China

Factory: Taizhou, China